All Categories

Featured

Table of Contents

- – Trailer Restoration Mira Loma, CA

- – OCRV Center

- – Travel Trailer Replacement Windows Mira Loma, CA

- – Trailer Restoration Mira Loma, CA

- – Travel Trailer Ceiling Repair Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Camping Trailer Repair Near Me Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Rv Travel Trailer Repair Near Me Mira Loma, CA

- – Camper Floor Repair Near Me Mira Loma, CA

- – Travel Trailer Roof Replacement Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Travel Trailer Furniture Mira Loma, CA

- – Rv Trailer Repair Near Me Mira Loma, CA

- – Travel Trailer Service Mira Loma, CA

- – Trailer Window Replacement Mira Loma, CA

- – OCRV Center

Trailer Restoration Mira Loma, CA

And then, brr, brr, must be able to simply drive some screws. The batten is simply acting like an actually large washing machine to make sure that that fabric does not have the possibility to tear through and come loose.

So the next point inside below is to seek a factor where we reach excellent product, and afterwards link into that with a new piece in a manner that structurally is gon na job. And likewise simply is basic sufficient to do. So, allow me get some devices gathered, and after that we'll take a look at out with the old and in with the brand-new right here.

Travel Trailer Replacement Windows Mira Loma, CA

I have actually obtained a bad end, conveniently identified, because that timber was in really, actually poor shape. And afterwards just considering the remaining lumber below. I'm searching for a part right here where it obtains audio. Currently, the other thing I understand is that beneath here, right there is a steel element of the trailer.

If I needed to come back additionally with the system I'm concerning to make use of right here, I would certainly be okay with that said. If in order to get rid of bad product, I needed to cut down here where I'm not over a steel framework component, I would certainly do that. What I've done so far lies the steel.

Trailer Restoration Mira Loma, CA

And the next thing, let's get that poor place removed. Jigsaw is a wonderful device for that. And what I want to do as I reduce is additionally lift a little bit. I wan na see to it the jigsaw blade doesn't penetrate the membrane layer down here. That worked out. And I have actually currently obtained a brand-new item cut.

There we go. The key to this are pieces of scrap plywood. And coupled with the plywood, we're going to add adhesive and screws, and that is actually gon na make this basically just like having one lengthy piece once again when we're done.

I have actually got in my hot little hands, an additional piece to go on that side. I just have to get my system out of the method here.

Travel Trailer Ceiling Repair Mira Loma, CA

This is a good application for it. As a result of making use of that, that belongs to the reason that I wished to make certain those battens obtained under the fabric. And the factor being that that mineral woollen, it's obtained some density to it. Now it's not that sitting there, I'm anxious regarding it caving in, specifically with the battens that I place underneath, yet just be cognizant that if you make use of that it does have some weight to it, and you wan na see to it that that fabric under the camper is gon na support that.

So when I'm reducing this piece, the item that's gon na complete right here, I want to maintain the manufacturing facility side on that particular end butting versus the factory edge that's currently in area, and after that the cut edge heads out right here up versus the wall. Currently, if you have to do a trim, you have to do a trim, and in this situation I did.

Trailer Roof Repair Mira Loma, CA

So if you obtained ta do it, you obtained ta do it, but it in the best world, factory side to manufacturing facility side right here on the long seams, and on the short seams where pieces are meeting. The various other point is that we intend to be fifty percent on a joist. So what I suggest by that is that this portion of plywood is half on this joist, and afterwards the next item of plywood is gon na begin here, so it's obtained something to be attached to, which's just a, you understand, a construction standard that you always comply with when you're doing floor covering or roofing.

There aren't any type of pieces of insulation laying on top of the framework. I have obtained, if you watch out right here, I have actually obtained these locations marked on the wall, to ensure that as I come along with a screw gun, extra on that particular in a 2nd, I understand that sleeper, that joist is there, center is there, facility is there.

Camping Trailer Repair Near Me Mira Loma, CA

I don't have a stapler that'll do that, but I do own a screw weapon that I can utilize to drive long screws. All right, a lot of speaking, and allow's look at getting the plywood to come in.

Well, we ended with a great deal of screwing around.The whole floor was a great deal of screwing about. Just a whole lot of little picky points to do to obtain this right, but definitely worth doing, because undoubtedly there were some poor spots in here that had to go. Trailer Floor Repair Mira Loma. With those screws, if there's any kind of area where you really feel like you may've missed out on, get a common cordless screwdriver, back those screws out

Trailer Roof Repair Mira Loma, CA

That takes care of this flooring task, and it was interesting, but I will certainly say, I rejoice it's done.

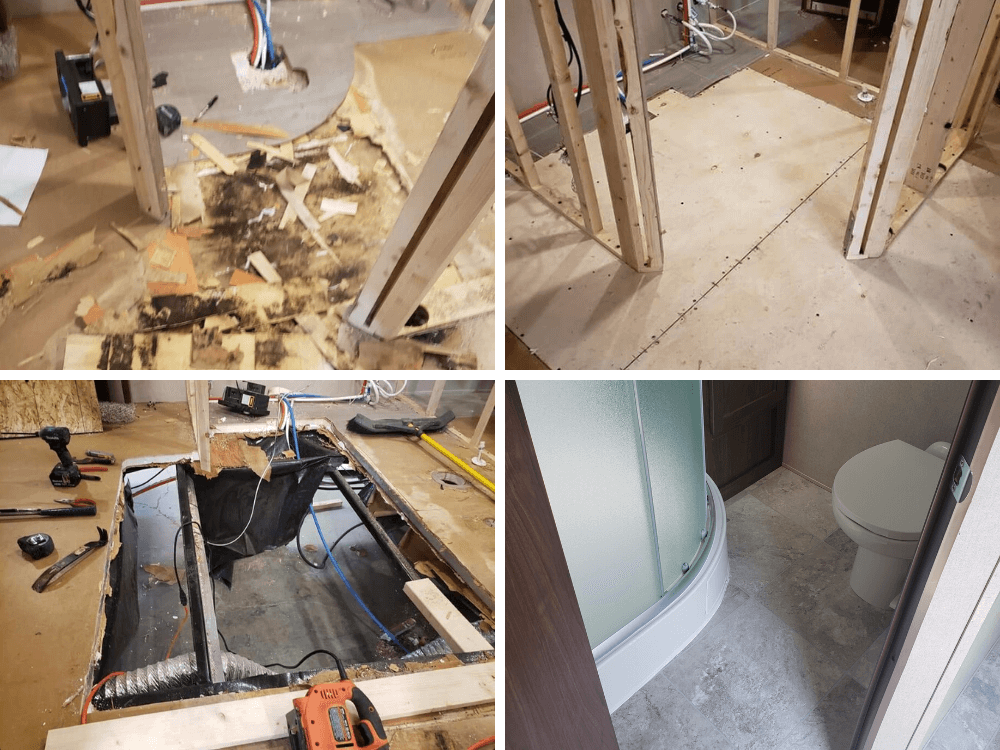

Most of the times, a rotten motor home floor shows a water leak someplace in the roofing system or walls, it might likewise be brought on by a leakage in the motor home's plumbing. Inspect the rotten location carefully. Check neighboring wall surfaces, home windows, the roof covering above, and any type of water lines or drain pipes in the location.

When you've situated every one of the soft spots, cut and peel off back the laminate or carpeting to expose the rotten subfloor. Some people choose to do this step really thoroughly, cutting along the wall surface, so they have the ability to make use of the same floor covering after the repair services are made. Regardless of exactly how you set about it, maintain peeling the floor covering back in all directions from the soft place till you situate good, solid timber that is not blemished on all 4 sides.

Rv Travel Trailer Repair Near Me Mira Loma, CA

This can be done making use of a tiny saw to reduce up the subfloor and a lever to dig the timber out. If there is foam under your subfloor, beware to eliminate the wood, however not the foam. If there are wooden assistances under your subfloor, you will desire to get rid of enough timber that you meet supports on at the very least two sides and then cut the opening to be a straight-sided rectangular shape to make things later on when including new wood.

You don't want any broken timber staying, as this can in fact trigger the brand-new wood to begin to rot throughout once more. When the harmed subfloor is gone, allow any type of exposed timber framing and the timber around the soft spot dry completely. This might take a week or even more, however it will help to ensure you will not come across the exact very same issue once you finish the motor home floor replacement.

Camper Floor Repair Near Me Mira Loma, CA

This can be accomplished with a sprayer utilized to use the antifreeze to the surface area of the timber, making certain to let the wood completely dry for a week or even more after.

It is likewise possible to inject the epoxy right into the wood for a lot more strengthening power. Depending on the hardener and epoxy that you purchase, you will certainly have anywhere from a couple of minutes to an hour to collaborate with it before it begins to set. You will certainly need to wait a week or two before the stuff solidifies completely.

You will certainly require to cover the recently laid subfloor. You could reuse the RV floor covering you brought up, however recreational vehicle floor substitute can be a wonderful chance to upgrade to a various product. Not exactly sure which type of floor covering is finest? Well, in locations that are prone to spills and dampness, like the bathroom and cooking area, you'll probably desire a plastic or laminate recreational vehicle flooring.

Travel Trailer Roof Replacement Mira Loma, CA

Because of utilizing that, that's part of the factor that I desired to make sure those battens obtained under the textile. And the factor being that that mineral woollen, it's obtained some density to it.

When I'm cutting this piece, the piece that's gon na fill in right here, I would certainly like to keep the factory side on that end butting against the manufacturing facility edge that's currently in area, and after that the cut side goes out right here up against the wall. Currently, if you need to do a trim, you have to do a trim, and in this case I did.

Trailer Roof Repair Mira Loma, CA

So if you got ta do it, you got ta do it, but it in the ideal world, factory edge to factory side here on the lengthy joints, and on the short seams where pieces are fulfilling. The various other thing is that we wish to be half on a joist. What I indicate by that is that this piece of plywood is fifty percent on this joist, and after that the next item of plywood is gon na come on here, so it's got something to be fastened to, and that's just a, you understand, a building and construction guideline that you always follow when you're doing flooring or roofing.

There aren't any chunks of insulation laying on top of the framing. I have actually got, if you keep an eye out here, I have actually obtained these places noted on the wall surface, so that as I come along with a screw gun, a lot more on that particular in a second, I understand that sleeper, that joist is there, facility exists, center exists.

Travel Trailer Furniture Mira Loma, CA

I don't have a stapler that'll do that, however I do own a screw gun that I can use to drive long screws. All right, a lot of talking, and let's look at getting the plywood to come in.

Well, we finished with a great deal of screwing around.The entire flooring was a great deal of screwing around. Simply a great deal of little picky things to do to get this right, but most definitely worth doing, since clearly there were some negative areas in below that had to go. With those screws, if there's any type of area where you feel like you could've missed out on, obtain a typical cordless screwdriver, back those screws out.

That cares for this flooring job, and it was fascinating, yet I will certainly claim, I am pleased it's done.

Inspect the rotten location very closely. Examine nearby wall surfaces, home windows, the roof above, and any kind of water lines or drain pipes in the area.

Rv Trailer Repair Near Me Mira Loma, CA

As soon as you have actually located every one of the soft places, cut and peel off back the laminate or rug to expose the rotten subfloor. Some individuals pick to do this action really thoroughly, reducing along the wall, so they are able to utilize the very same flooring covering after the repairs are made. No matter just how you go concerning it, keep peeling the flooring back in all directions from the soft place till you situate excellent, strong timber that is not stained on all 4 sides.

This can be done making use of a small saw to cut up the subfloor and a lever to dig the timber out. If there is foam under your subfloor, take care to remove the wood, yet not the foam. If there are wood supports under your subfloor, you will certainly desire to eliminate adequate wood that you meet supports on a minimum of two sides and after that reduced the hole to be a straight-sided rectangular shape to make points later on when including brand-new wood.

Travel Trailer Service Mira Loma, CA

You don't desire any type of damaged timber continuing to be, as this can actually cause the new wood to start to rot throughout once more. As soon as the harmed subfloor is gone, let any kind of subjected timber framework and the wood around the soft area completely dry out completely. This can take a week or more, but it will certainly aid to ensure you won't encounter the specific same trouble when you finish the recreational vehicle flooring replacement.

This can be completed with a sprayer used to use the antifreeze to the surface of the wood, making certain to allow the wood dry for a week or even more after - Trailer Floor Repair Mira Loma.

Trailer Window Replacement Mira Loma, CA

It is likewise feasible to inject the epoxy right into the wood for even more strengthening power. Relying on the hardener and epoxy that you get, you will have anywhere from a couple of minutes to an hour to collaborate with it prior to it starts to harden. You will require to wait a week or two prior to the stuff solidifies completely.

Not sure which type of floor covering is best? Well, in locations that are vulnerable to spills and dampness, like the washroom and kitchen area, you'll most likely want a vinyl or laminate Motor home flooring.

Trailer Roof Repair Mira Loma, CAFifth Wheel Repair Near Me Mira Loma, CA

Travel Trailer Repairs Mira Loma, CA

Rv Trailer Repair Near Me Mira Loma, CA

Trailer Windows Replacement Mira Loma, CA

Travel Trailer Floor Repair Mira Loma, CA

Trailer Window Replacement Mira Loma, CA

5th Wheel Repair Near Me Mira Loma, CA

Rv Travel Trailer Repair Near Me Mira Loma, CA

Travel Trailer Service Mira Loma, CA

Travel Trailer Ceiling Repair Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Travel Trailer Siding Repair Mira Loma, CA

Travel Trailer Awning Replacement Mira Loma, CA

Fifth Wheel Service Mira Loma, CA

Trailer Window Replacement Mira Loma, CA

Travel Trailer Roof Replacement Mira Loma, CA

Rv Trailer Repair Shops Near Me Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Horse Trailer Repairs Mira Loma, CA

Rv Trailer Repair Shop Mira Loma, CA

Horse Trailer Repairs Mira Loma, CA

Horse Trailer Repair Near Me Mira Loma, CA

Rv Trailer Repair Shop Mira Loma, CA

Travel Trailer Siding Repair Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Horse Trailer Repairs Mira Loma, CA

Rv Trailer Service Near Me Mira Loma, CA

Travel Trailer Siding Repair Mira Loma, CA

Camper Trailer Service Mira Loma, CA

Rv Trailer Repair Near Me Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Camper Trailer Service Mira Loma, CA

Travel Trailer Roof Replacement Mira Loma, CA

Travel Trailer Siding Repair Mira Loma, CA

Rv Travel Trailer Repair Near Me Mira Loma, CA

Fifth Wheel Service Mira Loma, CA

Travel Trailer Furniture Mira Loma, CA

Travel Trailer Service Mira Loma, CA

Rv Travel Trailer Repair Near Me Mira Loma, CA

Fifth Wheel Service Mira Loma, CA

Travel Trailer Roof Replacement Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Camping Trailer Repair Near Me Mira Loma, CA

Travel Trailer Repairs Mira Loma, CA

5th Wheel Repair Near Me Mira Loma, CA

Travel Trailer Ceiling Repair Mira Loma, CA

Rv Trailer Repair Shop Mira Loma, CA

Travel Trailer Repairs Mira Loma, CA

Fifth Wheel Repair Near Me Mira Loma, CA

5th Wheel Repair Near Me Mira Loma, CA

Travel Trailer Roof Replacement Mira Loma, CA

Camper Trailer Service Mira Loma, CA

Rv Trailer Repair Shops Near Me Mira Loma, CA

Trailer Restoration Mira Loma, CA

Camper Floor Repair Near Me Mira Loma, CA

Trailer Windows Replacement Mira Loma, CA

Camping Trailer Repair Near Me Mira Loma, CA

Trailer Roof Repair Mira Loma, CA

Camper Trailer Service Mira Loma, CA

Cargo Trailer Repair Mira Loma, CA

Rv Trailer Service Near Me Mira Loma, CA

Horse Trailer Repairs Mira Loma, CA

Travel Trailer Window Replacement Mira Loma, CA

Travel Trailer Floor Repair Mira Loma, CA

Travel Trailer Roof Replacement Mira Loma, CA

Rv Trailer Repair Near Me Mira Loma, CA

Trailer Window Replacement Mira Loma, CA

Rv Trailer Service Near Me Mira Loma, CA

Trailer Roof Repair Mira Loma, CA

Rv Trailer Repair Near Me Mira Loma, CA

Rv Trailer Repair Near Me Mira Loma, CA

Trailer Windows Replacement Mira Loma, CA

Rv Trailer Repair Shop Mira Loma, CA

5th Wheel Repair Near Me Mira Loma, CA

Trailer Awning Replacement Mira Loma, CA

Rv Trailer Service Near Me Mira Loma, CA

Fifth Wheel Repair Near Me Mira Loma, CA

Find A Good Seo Companies Mira Loma, CA

Around Here Seo Plans Mira Loma, CA

OCRV Center

Table of Contents

- – Trailer Restoration Mira Loma, CA

- – OCRV Center

- – Travel Trailer Replacement Windows Mira Loma, CA

- – Trailer Restoration Mira Loma, CA

- – Travel Trailer Ceiling Repair Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Camping Trailer Repair Near Me Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Rv Travel Trailer Repair Near Me Mira Loma, CA

- – Camper Floor Repair Near Me Mira Loma, CA

- – Travel Trailer Roof Replacement Mira Loma, CA

- – Trailer Roof Repair Mira Loma, CA

- – Travel Trailer Furniture Mira Loma, CA

- – Rv Trailer Repair Near Me Mira Loma, CA

- – Travel Trailer Service Mira Loma, CA

- – Trailer Window Replacement Mira Loma, CA

- – OCRV Center

Latest Posts

Fairbanks Ranch Tankless Water Heater Flush

Encinitas Water Heater Maintenance

Plumber Toilet Repair La Jolla

More

Latest Posts

Fairbanks Ranch Tankless Water Heater Flush

Encinitas Water Heater Maintenance

Plumber Toilet Repair La Jolla